Home > Case Studies > Aluminium Parts Washer

Industrial Parts Washer for Aluminium Parts

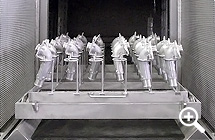

A company engaging in parts machining required an industrial parts washer for the cleaning and drying of aluminium parts.

Cleaning of aluminium parts

The parts washer had to clean at a rate of 24 parts every 4 minutes and remove coolant residue and chips from machining operations.

After cleaning, the particles present in the parts could not exceed 500 microns.

The customer preferred a cabin-type parts washer with manual loading and unloading.

Cabinet style parts washer

Spray wash cabinet with automated moving carrier, manufactured from stainless steel and with thermal and acoustic insulation.

Basket tailored for loading 36 parts in 5-6 minute cycles and stainless steel parts carrier with swinging movement performed by a pneumatic cylinder with four magnetic detectors for positioning thereof.

Treatment cycle:

- Spray-cleaning with hot alkaline solution (40 °C to 45 °C), preferably using demineralised water.

- Blowing with compressed air through blowing barriers distributed and oriented to sweep over the most conflictive areas of the parts.

- Drying by evaporation with pre-opening of front hatch.

In order to fulfil the cleaning requirements, the parts washer is fitted with a 300 micron filter housing and filter bag with a filtration capacity of 50 microns.

Cabinet washer with access hatches on either side, which is very useful for cleaning, maintaining and revising the interior thereof.

The parts washer also incorporates a detergent dosing device, a bimanual dashboard for emergency start and stop, a selector with/without blowing and an electrical box fitted with a programmable automaton and touch screen operator interface.

- HYDRORESA, S.L.

- C/ Fogars de Tordera 65

- 08916 Badalona (Barcelona)

- +34 932 327 217

- +34 932 314 971

- baufor@baufor.com